The new semester is just around the corner, and many colleges and universities "meet with each other deeply" with "a piece of plain paper" full of heart — —

Do you understand the "secrets" and words in the admission notice?

Harbin institute of technology admission notice information picture

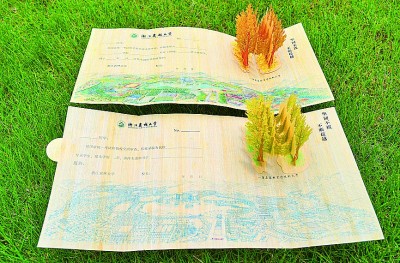

Zhejiang A&F University Admission Notice Photo by Chen Shengwei/Bright Picture

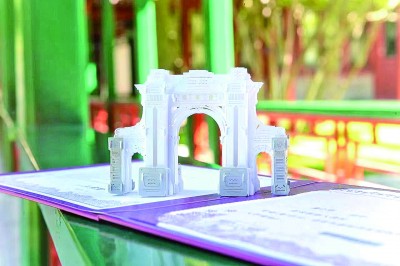

Tsinghua University Admission Notice Information Picture

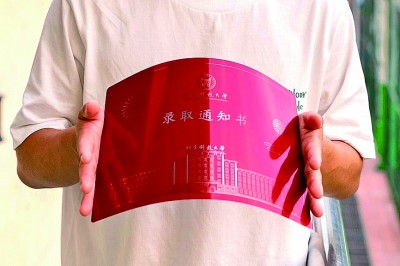

University of Science and Technology Beijing Admission Notice Information Picture

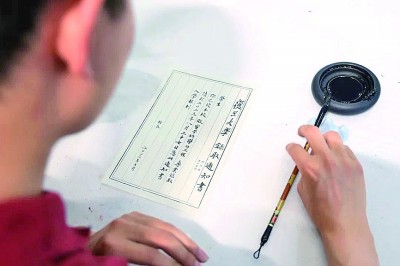

Handwritten admission notice information of students of Fudan University Painting and Calligraphy Association. Information picture

[narrating]

editorial comment/note

This summer, the admission notices of many colleges and universities were "fire". In the first "intimate contact" between freshmen and the university, the admission notices showing the history and culture of the university and bearing the characteristics and achievements of running a school are like "messengers", conveying the value pursuit and humanistic spirit of the school to freshmen.

What are the touching stories and ardent expectations behind the admission notice of "Fire"? We will take you to several teams involved in the design and production of admission notices, and in their speeches, we will feel the good intentions of "penetrating the paper" together.

Research and development of special coating escort "the country’s heavy weapon"

Narrator: Professor Wu Xiaohong, School of Chemistry and Chemical Engineering, Harbin Institute of Technology

This summer vacation, the special coating for spacecraft independently developed by our team was applied to bookmarks, and as part of the admission notice of Harbin Institute of Technology, we met the young students who were about to enter school.

Although the bookmark is small, it is full of science and technology, and the coating on it is very useful.

In 2017, I led the research team to participate in the development of the Tianwen-1 Mars orbiter. The flight of the orbiter from the earth to Mars is long and far away. How to keep the five-star red flag logo on the orbiter from fading and falling off in a long and extremely harsh environment? After more than a year of intense research, we have developed a special coating material with radiation resistance, low volatility and high and low temperature alternating resistance, and printed it on aluminum plate by special process, which solved this problem. On October 1st, 2020, during the National Day and Mid-Autumn Festival, when we saw the bright five-star red flag on the "Tianwen-1" ringer, we were deeply proud of our motherland’s birthday.

Resonant with the national major strategy at the same frequency, "based on aerospace, serving national defense and being good at engineering" is the long-term advantage of Harbin Institute of Technology. I have been thinking about how to combine my major with the needs of the country since I graduated as a doctor in 2003. After many investigations, I found an important link in the space field — — Coating the surface of spacecraft with functional coating is equivalent to putting on a multifunctional "coat" to improve its performance and reliability, but traditional technology can no longer meet this requirement. To this end, I will develop a new generation of special functional coating and protection technology for spacecraft as my research direction, and I am determined to become the realization of spacecraft functions and the guardian of safety.

In 2009, China’s lunar exploration project Chang ‘e-3 encountered a weight loss problem, and it was urgent to replace aluminum alloy with magnesium alloy chassis, but its application premise was to break through the technical bottleneck that it was difficult to prepare high heat dissipation coating on the surface of magnesium alloy. It is very difficult to coat the surface of magnesium alloy with high bonding strength, and it is even more difficult to have high heat dissipation function. We innovate independently, find another way, and have passed thousands of experiments — Failure — In the process of re-testing, the in-situ growth technology of thermal control coating with high bonding strength and high heat dissipation capacity was finally invented, and the application of light magnesium alloy chassis in spacecraft was realized, which successfully boosted the "the Goddess Chang’e flying to the moon".

In 2015, the high-temperature resistant and light-removing black coating is needed in the development of China’s FY-4 meteorological satellite, which is an important core material to ensure the detection accuracy. However, the existing imported coatings have the risk of polluting the lens and cannot meet the requirements of use, so they must be independently developed. After receiving this arduous task, my team and I worked tirelessly day and night to successfully develop a low-pollution and high-performance matte black coating. In December 2016, the Fengyun-4 satellite was launched, and its comprehensive observation capability on the earth was leading the world.

In more than 20 years of scientific research work, we have caught up with the good times of vigorous development of China’s space industry. While making breakthroughs in scientific research, my team and I have gained valuable growth.

In the past, chemistry, materials, biology, and environment were rumored to be the four "Tiankeng" majors, which is actually a misunderstanding. The new material industry is a strategic and basic industry, and also a key field of high-tech competition. The country’s development of emerging industries and high technology can not be separated from materials, and its prospects are very broad. I think, this notice is to tell young students with our story: always combine your ideals and aspirations with the major needs of the country, and you can achieve a valuable life.

The paper that is not bad for thousands of years writes shining youth

Narrator: Yang Guanghui, Executive Vice President of Chinese Ancient Books Protection Institute of Fudan University.

This summer, the admission notice sent to every Fudan University freshman used a special kind of paper — — Kaihua paper In the words of president Jin Li, "it carries the ancient papermaking technology and Fudan advanced technology, and explains ‘ Be knowledgeable and determined, ask questions and think closely ’ The spirit of ". This "Chinese Romance" begins with Yang Yuliang, an academician of China Academy of Sciences, former president of Fudan University and president of China Ancient Books Protection Research Institute.

Traditional writing and printing materials — — Paper and ink are both polymer materials. For a long time, the core problem in the protection of ancient books is to repair materials, and the difficulty is the lack of paper suitable for repairing ancient books. As the first generation of polymer scientists trained in New China, Academician Yang Yuliang faced up to difficult problems and led the scientific research on core writing and printing materials such as paper and ink.

The eyes of exploration are cast on the people. Academician Yang gradually locked in the ancient paper "Kaihua Paper". He found that Huang Hongjian and others in Kaihua County, Quzhou, Zhejiang Province, had been engaged in the recovery process of kaihua paper for many years, but they were unable to find a way out for many years because of the lack of modern scientific and technical guidance. Therefore, Academician Yang personally visited Kaihua County and set up an academician workstation, which opened the prelude to the recovery of the newly opened paper technology.

Academician Yang started with the establishment of a biological and chemical research team related to paper research. Through field visits to Kaihua Paper, Jiangxi Qianshan Lianshi Paper, Sichuan Jiajiang Zhuangyuan Red Paper, Anhui Jingxian Xuan Paper, Fujian Liancheng Lianshi Paper, Japanese Mino Paper, Egyptian Cypress Paper, and Israeli Dead Sea Scroll (sheepskin Book), members of the team gradually learned about the production, restoration and application of handmade paper in the world, and visited the Writing Culture Research Center of Hamburg University in Germany.

Basically, the main papermaking raw material is Wikstroemia beijiangensis. However, there is a serious shortage of wild resources, poor standardization of collection, and lack of standardized process and index system for processing. To this end, Professor Zhong Yang, who is in the direction of biological research in the team, led the members to tackle key problems, fully analyzed the diversity and genetic structure of the varieties of Ligusticum wallichii, and gradually established an artificial rapid propagation system of papermaking plants based on artificial planting and tissue rapid propagation.

With raw materials, bleaching has become a new "roadblock". Dr. Xie Shoubin invented the "Non-destructive Bleaching Method", which used laccase to bleach the phloem fiber of Toona sinensis to a whiteness far exceeding that of rice paper, and the key factor that determines the paper life in pulp — — The polymerization degree of cellulose is not reduced at all, which can ensure the immortality of the paper for thousands of years. In addition, the team also put forward different paths and sequence of cellulose degradation in the paper of Kaihua Paper under the conditions of dry heat and wet heat. By measuring the degree of polymerization and crystallinity, the service life of newly-made Kaihua Paper was determined to ensure the quality of Kaihua Paper … …

With the intervention of science and technology, Kaihua paper has been reborn, used in the restoration of ancient books, printmaking and painting creation, and also used to make the admission notice of Fudan freshmen, showing the wonderful integration of science, humanities and art. Fudan students who received the admission notice of Kaihua Paper can also experience the integration of tradition and modernity, giving birth to endless imagination and enthusiasm. I expect them to use the pen of struggle to write the shining youth on the Millennium-old paper.

Steel as thin as cicada’s wings engraved with burning heart

Narrator: Fiona Fang, chief engineer of tinplate in Technical Research Institute of Shougang Group Co., Ltd. and Ph.D. student in materials science and engineering, University of Science and Technology Beijing.

The undergraduate admission notice of University of Science and Technology Beijing "steel as paper" made a stunning appearance. The main body was made of "5G steel" as thin as cicada’s wings and as light as a mirror, which was jointly developed by Beijing University of Science and Technology and Shougang. Behind the notice, there is a counterattack story of China’s scientific research team "from catching up to leading".

5G steel, also known as cicada wing steel, is famous for its thin thickness. To develop such a thin steel, it is a big problem to refine inclusions. For example, the thinnest thickness of high-end automobile panels is 0.5 mm, and the size of inclusions is required to be no more than 50 microns. The thinnest thickness of cicada wing steel is only 14% of the automobile panel, and the size of inclusions should be further reduced by more than 60%, and the maximum size should not exceed 20 microns. Only a few advanced steel enterprises in the world have mastered this technology, and the continuous casting cycle is long and the production efficiency is low.

We set up a scientific and technological team of Cicada Steel, and based on the clean steel production platform of Shougang Jingtang Company, put forward the idea of step-by-step control of inclusions. Based on the strategies of low oxygen tapping in converter, refining and anti-agglomeration, intensified removal of tundish and control of mold flow field, we took the lead in achieving high efficiency and high cleanliness.

After tackling the problem of inclusions, another bottleneck is ultra-thin tandem cold rolling. Generally speaking, the thinner and wider the steel, the more difficult it is to roll. In the field of low carbon steel technology, advanced steel enterprises at home and abroad adopt acid continuous rolling — Annealing — Double stand secondary cold rolling process, the international thinnest thickness is 0.10mm, and the maximum width-thickness ratio is 7500. Under the traditional technology, acid continuous rolling and secondary cold rolling have large reduction rate and high rolling load, and the specifications below 0.16 mm have high requirements on the control stability of tension and rolling force during secondary cold rolling, so it is extremely difficult to produce efficiently and stably.

Without precedent at home and abroad, team members "brainstorm" again and again. Since no breakthrough can be made under the existing conditions, why not change the existing conditions? Therefore, the team put the breakthrough point on the tension and decided to increase the tension to effectively reduce the rolling force, thus achieving thickness reduction.

In traditional rolling, the tension is usually 30%~50% of the yield strength of the material. If it is increased to more than 50%, it will easily lead to local cracking or even tensile fracture due to small fluctuations. Sure enough, at the beginning of the test, when the tension is increased to more than 60% of the yield strength, we often hear a bang — — Rolling belt breakage occurred. Sometimes, it even breaks two or three times a day. After careful analysis of the reasons, we finally found that the slight fluctuation of strip thickness will lead to tension fluctuation of more than 50%, which will lead to belt breakage. A new problem arises: how to reduce the tension fluctuation problem under large tension? After repeated explorations, we finally shortened the response time to one-third of the original by changing the traditional rolling strategy and control system, and achieved stable rolling with ultra-large tension. The thinnest thickness broke through from 0.10 mm to 0.07 mm, and the maximum width-to-thickness ratio broke through from 7,500 to 11,400, creating a new world record and strongly supporting the reduction of 5G equipment.

Nowadays, the annual output of iron and steel manufacturing industry in China ranks first in the world. We have won the top spot in many aspects, such as "cicada wing steel" and "hand-torn steel", but there are still many "stuck neck" problems to be overcome. I hope that the younger brothers and sisters who are about to enter the campus will cherish their youth and be brave enough to be the "steel backbone" on the road to rejuvenation.

Bamboo bearing brocade tells green stories.

Narrator: Wang Tao, head of the bamboo admission notice research and development team of Zhejiang A&F University.

Relying on the university’s scientific research advantages in the field of bamboo research and bamboo processing, we have developed the admission notice with bamboo as the raw material and micro-sliced bamboo technology as the core for 9 years in a row, and have been iteratively upgraded with new patented technologies, and the related technologies have won 8 national patents.

The research and development of bamboo admission notice began in March 2015. At that time, although the technology of slicing meager bamboo was mature, it was still difficult to make an admission notice. We spent nearly two months, through technical innovation and repeated printing of samples, and finally made a sample of admission notice with a thickness of 0.75~0.8 mm on May 30 of that year. In order to solve the problem that bamboo is easy to break when folded in half, every admission notice uses double-layer sliced bamboo, and ultra-thin non-woven cloth is embedded in the two-layer sliced bamboo, combined with laser breakpoint punching technology, which avoids the risk of breaking well. At the same time, advanced technologies such as hot pressing, anti-corrosion and printing are used to ensure that the admission notice is legible, pressure-resistant and folding-resistant, and easy to collect and preserve.

Since then, we have continuously tried to strengthen the strength of composite bamboo and reduce the thickness of the material, thus realizing various technological innovations. For example, in 2020, starting with the flexibility and mildew-proof technology of bamboo substrate, the characteristics of strong flexibility, arbitrary curling and folding, non-toxic, harmless and mildew-proof were realized; In 2021, the flexibility and light transmittance were further enhanced; In 2022, began to explore the country’s first 3D handmade bamboo admission notice … … Now, there is no waste water or waste liquid in the process of making our admission notice. The whole process is green and environmentally friendly by using modified starch adhesive and manual 3D production, which fully embodies the concept of ecological civilization.

The 2023 version of the admission notice not only continues to be hand-made in 3D, but also is thinner and firmer, with the thickness almost equal to that of three ordinary A4 sheets, which can be folded in half at will, pressed sideways, and even curled into a shaft like paper.

Bamboo is an important carrier to record history and culture, and also an eco-friendly material with strong carbon sequestration capacity. The bamboo admission notice not only has cultural attributes and scientific and technological content, but also conveys the value concept of advocating ecology, developing science and technology and promoting culture to freshmen.

Over the past few years, our design team has been expanding in the design, production and iterative upgrade of the admission notice. Looking forward to more green "seeds" sprouting and growing on campus, adding color to the beautiful China.

Project team: reporters John Zhang, Zhang Shiying, Yan Weiqi, Chen Peng, Lu Jian, Wang Simin Trainee reporter Li Jiaxin correspondent Chen Shengwei.

关于作者