Food enterprises and supply chain are inseparable, and win-win cooperation between front-end and back-end is the only way for the future catering industry.

This article is a record of the round-table forum at the "2024 China Catering Industry Summit", which was reorganized and released by Red Dining Network.

With the catering gradually entering the stage of "ten thousand stores chain", more and more catering enterprises begin to pay attention to the ecological construction of the whole industry, and constantly improve the whole closed loop from the origin of raw materials, factories, warehousing and logistics to store operation.

For the catering industry entering the era of low profit, opening up the whole industrial chain means reducing costs and increasing efficiency, which can further enhance the stability of enterprise development and help enterprises enhance their ability to resist risks.

Under the new trend of the industry, how can head catering enterprises and supply chain enterprises develop together better?

At the "2024 China Catering Industry Summit", Zhao Min, founder of Mufeng Supply Chain, Liu Zheng, president of Ziguangyuan Group, Chai Lei, founder of Liangquan Qimei Group, Yan Dongsheng, inheritor of Chongqing Hot Pot by Pei Jie, li ke, co-founder of Baipin Sunlight Tomato, Zhang Li, founder of Lisike Barbecue Supply Chain, and Wu Huiling, industrial investment partner of Wuyi Qi, conducted in-depth discussions on "the coordinated development of catering chain brands and supply chain enterprises".

01. Chain stores are locked together, and the supply chain is an important link.

Zhao Min: In the past two years, we have seen more and more catering enterprises extend to the upstream end of the industry and build a whole industrial chain. New tea will build a fruit raw material planting base, fast food enterprises will buy meat and poultry processing plants, hot pot enterprises will increase bottom materials, and compound seasoning production lines … In 2024, I am afraid that the bets of chain restaurant enterprises on the supply chain will increase.

Although all of you here come from different segments, you also have an understanding of the catering supply chain, so I would like to ask you first, how do you view the catering enterprises accelerating upstream? What impact will this bring to the whole catering ecology?

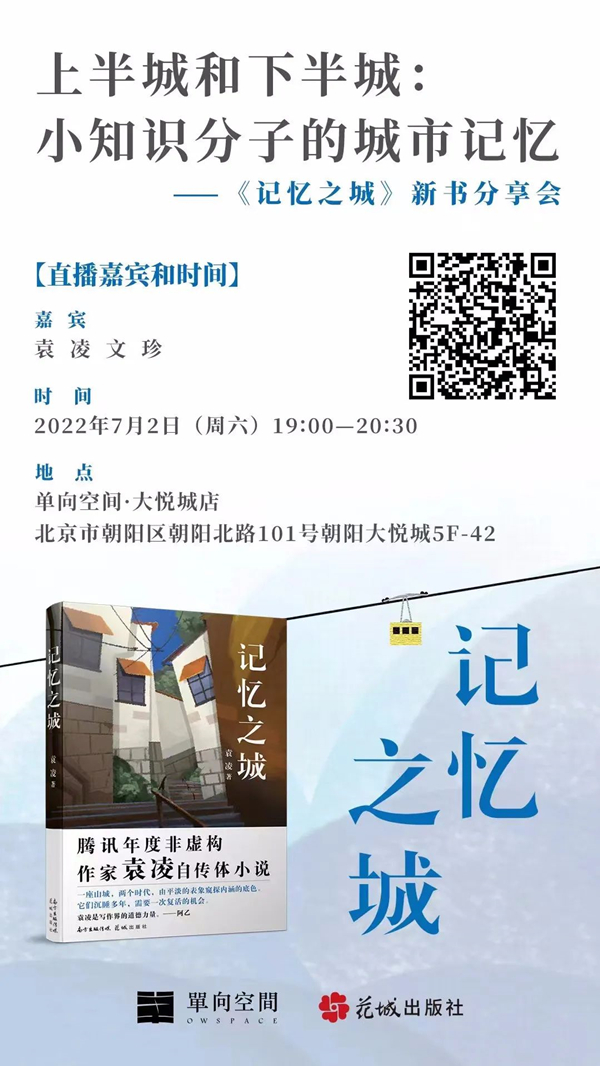

Li ke: Good morning, everyone. I’m li ke from Baipin Solar Tomatoes. We specialize in various seasoning products of tomato series. We are a supply chain enterprise, with deep links with food enterprises.

△ li ke, co-founder of Baipin Solar Tomato

At the beginning, the relationship between catering enterprises and supply chain enterprises was only a simple supply relationship. Now catering enterprises have more customized needs, so they will go upstream to create products with us.

At the end of last year, we jointly created a "golden tomato pot" with Zhu Guangyu, and the two sides set up a joint team to do it together, which is equivalent to you and me. This is a case that I have a deep experience.

I think the most important thing for food enterprises and supply chains is to do their own quality well and make their own characteristics. For Baipin, we just do 16 words-"Be awed, keep loving, take the initiative to evolve and achieve the ultimate".

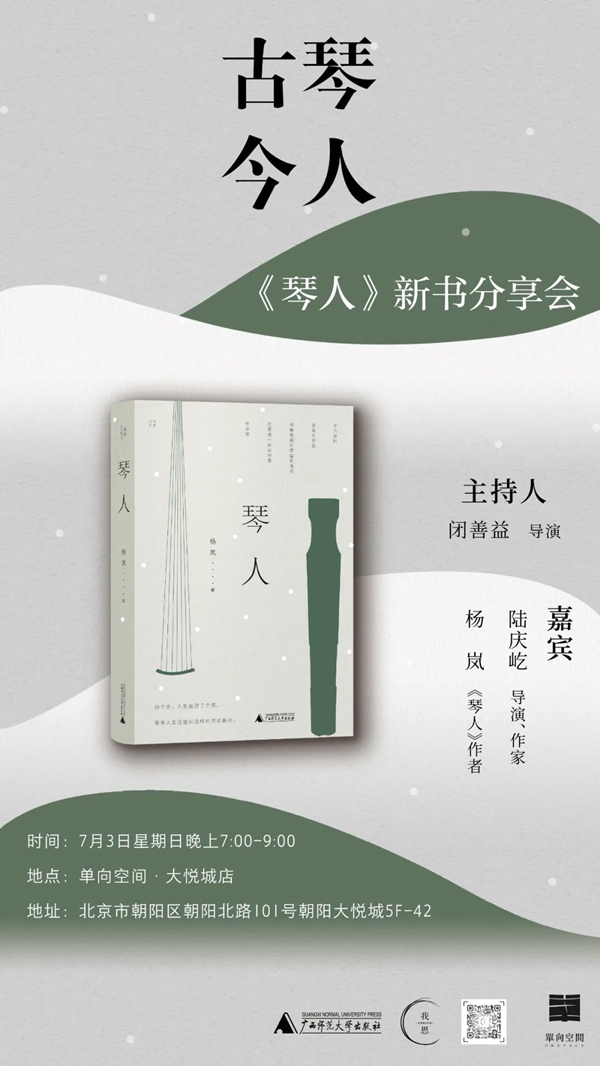

Chai Lei: Quanqimei was founded 20 years ago. At first, it was an accidental opportunity. We found the onion-grabbed cake in Taiwan’s night market. We took this product back to the mainland and renamed it "Taiwan Province finger-grabbed cake". Later, it was directly called finger-grabbed cake.

In the past 20 years, we have been iterating over the business model, from roadside shops to fast-moving consumer goods. I think there is no difference in size between products. The most important thing is to study it thoroughly and thoroughly.

We started as a small restaurant. When there are more and more chain stores, the whole chain system is very weak because of the lack of supply chain support. Supply chain is very important to "lock" large-scale chain stores together.

△ Chai Lei, founder of Liangquan Qimei Group

The development of upstream supply chain depends more on the needs of enterprise development stage, scale and product differentiation. If we want to make differentiated products, the supply chain must be built by itself. When the scale is relatively large, or the products are relatively homogeneous, I personally think it is better to cooperate with supply chain enterprises. There is a division of labor between the society and the market, and it is impossible to do it all by ourselves and control the competitiveness of core products.

Catering enterprises cooperate with the upstream supply chain, so that the whole industry will be relatively more professional at different stages, and the pressure will not be too great. Just like hot pot restaurant enterprises, in terms of product structure, there are many ingredients besides seasonings, so they have to rely on cooperation. Moreover, producing hot pot bottom materials by themselves is not necessarily better than deep cooperation with partners in research and development, and it has advantages in cost or organizational ability.

Food enterprises are inseparable from the supply chain. From the perspective of entrepreneurs, we should stick to our own focus and make it more professional. When you do one thing well and others lack this section, they will come to you.

02. Win-win cooperation between front-end and back-end is the only way for future catering.

Liu Zheng: Ziguangyuan is an old brand. At present, there are 180 direct stores, all of which are in Beijing. The layout of Ziguang Garden in recent years is summarized as "three transformations and five horses".

The first of the "three modernizations" is the retail of catering. Ziguangyuan has done convenience, people’s livelihood and retail in recent years. Second, the channels are diversified. The gene of Ziguangyuan is to be a big store, and it is to be a direct restaurant. However, in the past four years, we have launched "one store and six shops". The third is product enrichment or online and offline integration. When you go out, you will eat Ziguang Garden for generations. We hope Ziguang Garden can reach every diners who come to Beijing.

△ Liu Zheng, President of Ziguangyuan Group

"Five Horses", first of all, the main brand Ziguangyuan is a horse; The second horse is the e-commerce channel of Ziguangyuan, and it is delivered home; The third horse is To B business; The fourth horse is the To C retail business of the mall; The fifth horse is the group meal business of Internet companies. Because of this layout, Ziguangyuan began to integrate and build its own supply chain. Last year, it invested 120 million yuan to build a strong back-end, which changed from fixed production by sales to fixed sales by production.

Front-end and back-end cooperation and win-win, I think it is the only way for future catering. Ziguangyuan will revolutionize people’s catering to the end, and hope that the source and upstream enterprises of the supply chain will communicate and cooperate with us more.

Yan Dongsheng: Pei Jie Hotpot was founded 10 years ago, and has traveled from Chongqing to Shanghai, Shenzhen, Guangzhou, Beijing, Hangzhou and other cities, making Chongqing Hotpot the first in the national direct sales scale. We went from small stores to big stores and then to many stores. In order to ensure better quality and lower cost, we also built factories in the upstream, but now we stop going upstream and focus more on opening stores in the front end.

Sister Pei is now cooperating with Sichuan Lahai, which has a large volume, guaranteed quality and low cost.

I also agree with Chai Lei’s general view that there are specialties in the industry, and the product quality of many supply chain enterprises is completely up to standard. We also have small factories, but with the increasing volume, we mainly cooperate with supply chain enterprises now.

△ Image source: Pei Jie Chongqing hotpot

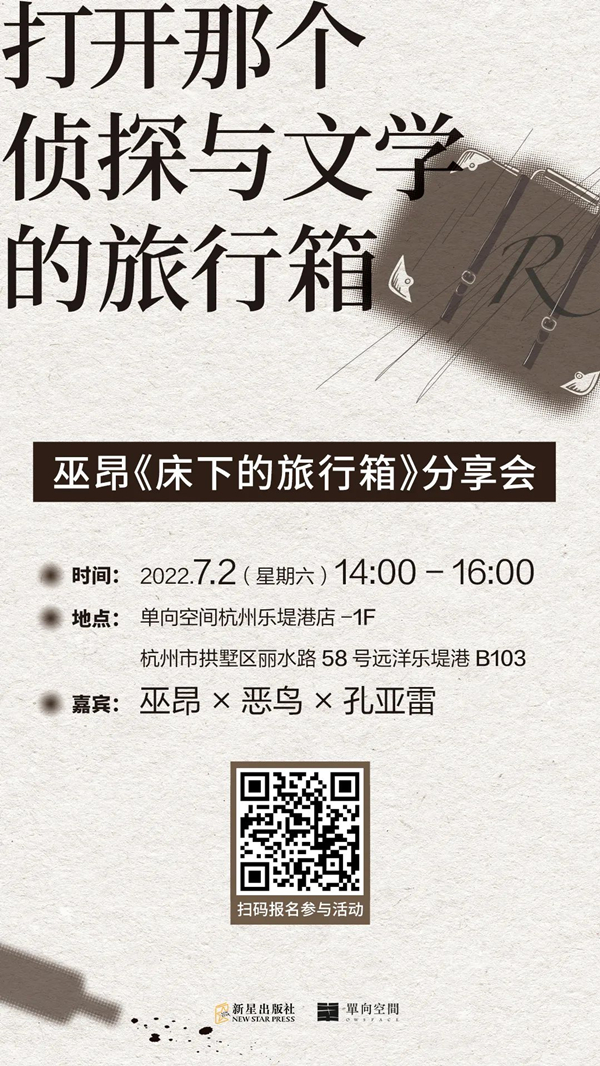

Zhang Li: My supply chain enterprise is Lisike. I used to run a restaurant ice city string. What everyone said just now is very reasonable. The end of the world is joining, the end of catering is retail, and the end of chain is supply chain. The future competition is not the competition between brands, but the competition between supply chain and supply chain.

The supply chain behind each category will probably lag behind the development of this category for 3-5 years. At present, the barbecue supply chain is still a blue ocean. In some areas, there are still categories without brands, strong brands and large national chain brands, but there will be in the future, because barbecue is the second largest category of catering in China. So I firmly chose to be a supply chain 10 years ago, and now I have three factories serving many big brands.

△ Image source: Liske official website

I think the whole restaurant chain business has a long chain from the field to the dining table. The front-end system is the brand end, the brand is operated and the brand is marketed, and the back-end is supported by the supply chain. The supply chain is an important force behind the brand, which covers the conversion of various information such as purchasing, warehousing, distribution and production. Therefore, the future cross-regional development and transnational development must require a strong supply chain system, and Lisike is a manufacturing supply chain.

Wu Huiling: Wuyiqi Industrial Investment is an accelerator that focuses on "eating" capital, and light catering and specialty foods. In recent years, we have invested in more than 50 brands such as Qianweiyang Kitchen, Enxi Village, Qianwei Soup, Momoko, Shuyi Xiancao, Xiaolongkan, Shu Daxia and Jixiangju, most of which are leading enterprises in sub-sectors.

△ Wu Huiling, industrial investment partner of Wu Yi.

In the long-term observation, research and practice, we have summarized nine core elements of catering franchise chain, including product mix, single-store model, franchise system, brand potential, channel intensive cultivation, digital growth, capital resources, supply chain, organizational talents, etc. Among them, supply chain is a very important element. Only by realizing the closed-loop system from raw material origin, processing factory, warehousing and logistics to store operation can we ensure the stability of product supply, cost control and realization.

This is also the reason why many chain catering enterprises pay more and more attention to the ecological construction of industrial chain. Of course, the way of construction is diversified, and different restaurant chain brands need different supply chain capabilities at different stages. In the chain operation, brands with more than 100 stores can’t be locked without a supply chain.

Therefore, it is an inevitable stage, or an inevitable trend, to build a supply chain in the chain of catering enterprises. I hope that food enterprises and supply chain enterprises can foster strengths and avoid weaknesses, and achieve win-win integration.

03. Realize the closed loop of industrial chain from raw materials, varieties, quality control and innovation.

Zhao Min: Mr. Li, how is your upstream supply chain built? How to achieve a closed loop in ingredients, quality control, and the entire industrial chain?

Li ke: We are an enterprise that makes tomato seasoning. Ten years ago, tomato was still a relatively small flavor, but it has a strong consumption base in China, and people of all ages like it. From the perspective of the whole world, Europe, Japan, Southeast Asia and other countries use tomato flavor more than we do. So we made this taste, and when we did it, there were also great challenges. We mainly did three things well.

The first thing is to find high-quality tomato producing areas and tomato raw materials. Good ingredients or products must have good raw materials. The tomatoes used in our tomato soup base are not quite the same as the tomatoes we eat every day. The world’s three major tomato producing areas, California in the United States, the Mediterranean coast and Xinjiang in China, China happens to be one of them, so we have chosen good raw materials. Many people ask, Xinjiang is so far away, can we transport tomatoes back well? It took us nearly five years to get through the processing technology.

The second thing is to choose varieties. There are 1078 varieties of tomatoes recorded in China, and now there are 5 varieties in our bottom material. To tell the truth, the products of Baipin Nikko in the first three years failed to meet my highest requirements, and now they are the fifth generation products. We upgrade them every year, constantly test them and make changes in varieties.

The third thing is to do a good job of quality control. In the face of tomato, a popular agricultural product, it is more important to look at a series of indicators from seedling raising and sowing to pesticide residues in the whole raw material. We have 79 internal control standards to ensure the stability of tomato.

Finally, there is continuous innovation. In the future, we may introduce tomato varieties from Spain, Italy or the United States. In addition to red tomatoes, there are yellow, purple and black tomatoes, which will continue to empower diners.

In the field of tomatoes, our scale is not necessarily the largest, but we love tomatoes very much, and we will do this for the next 10, 20 or even our whole life.

Zhao Min: Barbecue is a big track in the catering industry. The market scale has exceeded 220 billion yuan, but there is still no head brand with more than 1,000 stores. What do you think is the reason for this situation? From the experience of Lisike, what are the difficulties in the supply chain of barbecue category compared with other categories?

Zhang Li: Actually, the brand of thousands of stores will see this year, and now there are brands that have exceeded 800 stores.

I think the fulcrum of every enterprise is the product. For Lisike, others couldn’t solve my problem at that time, so I chose to build my own factory and shifted my focus from front-end stores to back-end supply chain. This is the change of our enterprise and the whole catering industry.

There are many difficult things, including production, management and research and development. It took us 10 years to know how to operate the factory, how to manage quality control, how to do research and development around customer needs, how to ensure supply, and how to make the customers and brands we serve safer and more reliable.

△ Zhang Li, founder of Lisike barbecue supply chain

In recent years, I have found that the founders of barbecue brands with less than three stores and more than three stores think completely differently. Brands with more than three stores are eager to break through the supply chain, and within three stores, they are still iterating from 0 to 1, from no cognition to cognition.

Lisike has two types of customers, "barbecue+"and "+barbecue". The standardization of barbecue is particularly high, and the supply chain is relatively concentrated. The animal protein ingredients such as pigs, chickens, cows and sheep that we are making now are very suitable in various stores or various formats. We have also worked out how to achieve extremely high standardization and turn store products into standardized products that can be produced in factories, thus solving the problems of bakers, standards and continuous supply.

04. To build the ultimate supply chain, all around the scene and demand.

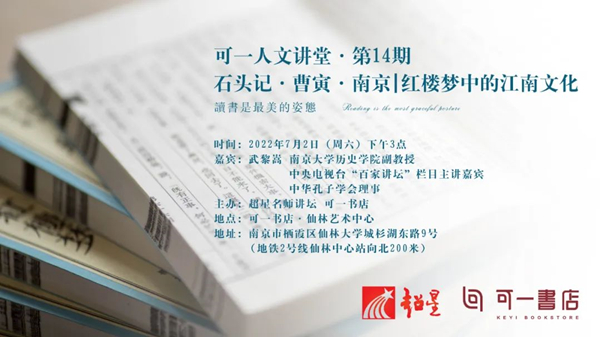

Zhao Min: The competition in the catering industry is very fierce, and it has entered the era of meager profit. Under this situation, everyone is trying to create the ultimate efficiency and experience. How do they work hard on the two "extremes" in the development process of grasping cakes?

Chai Lei: Although we are just making a cake, it is still very difficult. The difficulty is that the demand is constantly changing.

Our current stores are basically overseas, and the supply side is more complicated. What we considered before was how to build a supply chain in China to serve small restaurants. At that time, the process was reformed to reduce manufacturing costs and improve efficiency, and the store side tried to maximize the menu structure. However, the factory solved the problem of cost and efficiency, but the consumer didn’t pay the bill. He felt that your product was too single, which made it difficult for a store to survive.

△ Image source: The food is all beautiful in official website

Then, catering enterprises whose products are supplied to different channels and services will also bring greater challenges. At present, we supply cakes used by many catering enterprises. How can we cooperate with these catering enterprises in the supply chain? At this time, we should not only consider one product, but also consider how to serve cakes quickly in the store and how to combine them with the core products of the store. This also involves different catering segments, and the needs of customers are also diversified.

Online, different channels, such as Tik Tok, JD.COM, Pinduoduo, Tmall, etc., have different ways of playing, and the domestic channels are different from overseas.

As for whether to reform the process at the factory end, the dynamic line of the store, the production of equipment, the semi-prefabrication, or a formula of the product itself, we need to do detailed research. For example, we supply our own chain stores, which are different from those that supply hot pot and supermarkets. In short, everything revolves around the scene and demand.

Zhao Min: At present, the three elements of "people and goods yard" in catering business have all changed, and consumers are more concerned about cost performance. franchise chain, take-out and e-commerce retail channels have become new growth points. In the face of these changes, what is the new planning and layout of Ziguang Garden?

Liu Zheng: Shopping malls are like battlefields. Next, Ziguang Garden should unify its thinking and build organizational strength in strategic direction, strategic deployment and strategic objectives. Then the battle started. At present, Ziguangyuan has started 12 major battles; Then play tactics-one shop and six shops; This is the supply chain.

△ Image source: Ziguangyuan official blog

In 2024, Ziguangyuan will be "fully armed" and put into the catering "battlefield". In the future, a series of battles will be fought around eight words:

The first is sincerity, and sincerity is always your best card. From source procurement to processing, have we cooperated with the supply chain in good faith? We should use a sincere heart to achieve common and sustainable development.

The second is conscience, which should create value for partners and customers and make food with conscience.

The third is trust, so that consumers can trust you and bring warmth to their hearts. Some time ago, two hot searches, "Ziguang Garden is the restaurant with the heaviest sense of’ human kindness’ in Beijing" and "Beijing cuisine depends on a bowl of yogurt", showed customers’ trust in the depth of Ziguang Garden, which was a praise for the fireworks and human feelings created by Ziguang Garden, and fireworks were also the value created by Ziguang Garden for customers.

The last two words are peace of mind, down-to-earth, and making a brand of trust with conscience, so that customers can feel at ease and the brand can last for a long time.

05. Five modes of coordinated development of catering enterprises and supply chain

Zhao Min: At the beginning of March, Sister Pei announced the opening of franchise, and insisted on direct management. Sister Pei had previously let go of franchise, so for what reason did Yan always choose to let go of franchise again? What measures will Pei Jie take to ensure the stability of the store’s products?

Yan Dongsheng: Pei Jie’s Chongqing hot pot has traveled from Chongqing to Shanghai, Shenzhen, Hangzhou and other cities in the past ten years. She has been deeply involved in direct sales, and there are more than 30 direct sales stores. The performance is very good in the industry. We make authentic Chongqing hot pot and operate quality.

△ Pei Jie Chongqing hot pot inheritor Yan Dongsheng

We once let go of joining, but we didn’t control people and supply chain and couldn’t meet the quality requirements, so we suspended it. With the deep cultivation of direct stores for so many years, we have gradually improved the management system, operation system and quality control system, and we also want to expand rapidly, hoping to find partners with real estate resources to open stores together.

Franchising now is different from before, and each store is directly managed by Pei Jie’s headquarters, so as to ensure the quality and make authentic Chongqing hot pot.

We let go of joining in order to find more resources. Everyone empowers each other, and the brand’s initial heart and genes have not changed.

Zhao Min: From the perspective of management, what trends do you think may appear in the future in promoting the deep cooperation between restaurant chain brands and supply chain enterprises? What aspects will you pay special attention to when investing in the catering supply chain?

Wu Huiling: From our long-term observation, there are five modes for the coordinated development of catering enterprises and supply chains.

The first type is called completely self-built and self-harvested. If it is completely self-built, from the field to the dining table, it may be unbearable for the general chain enterprises, and the investment is too heavy, so it is not particularly suitable.

The second mode is complete outsourcing. For example, a chain catering enterprise with 30-50 stores may choose a supplier similar to Shuhai to outsource, which may be a more cost-effective mode.

The third type is nested with each other. Core categories are self-built supply chains, such as central kitchens or factories, and others are imported. Self-built factories not only meet their own supply, but also open to other enterprises and nest with each other, which may be the mainstream way in the future.

The fourth is the scene specialization mode, which is specialized in a certain category of supply chain, such as group meals, country banquets, barbecues and hot pots. For example, there are many hot pot chain brands in Sichuan that share a supply chain factory. Scene specialization mode is also an important direction in the future.

The fifth is close cooperation, but it does not involve equity cooperation, such as OEM mode (a mode of OEM production), or customized cooperation that is very popular now.

What kind of mode an enterprise uses and suits itself depends on its resources, development stage, and the balance of scale, cost and efficiency.

From the perspective of investment, we will pay attention to the "three products" when choosing the target. The first is the category, and the ceiling of the category should be high enough. The second is quality. It is best for this enterprise to be a head enterprise in a subdivided field or have the genes to become a head enterprise. The third is character, that is, an entrepreneur must be a person with conscience, industrial structure, concentration and sharing.

Specific to catering supply chain enterprises, we will also pay attention to whether enterprises have really solved some pain points in the industry value chain. Is the product addictive or the service dependent? Does it have the characteristics of super supply chain such as high cost performance or high turnover efficiency, etc.

(Note: This article belongs to the catering industry information published by Yangguang. com. The content of this article does not represent the views of this website, and it is for reference only. )